As a piece of engineering, the human body is a marvel. It maintains its balance even while executing complicated movements; it senses and adapts to heat and cold. Every 20 seconds, it circulates blood through even its most far-flung extremities. It has cells capable of replacing wounded tissue, finding and destroying dangerous invaders, and interconnecting to produce thoughts and emotions. Utilizing all these functions, our bodies—and all living systems—can accomplish tasks far more sophisticated and dynamic than any artificial entity yet designed by humans.

Harvard’s Wyss Institute for Biologically Inspired Engineering (wyss.harvard.edu) is taking on the ambitious task of applying the astounding capabilities of living systems to better engineer artificial ones. Its projects range widely: robots that self-organize, materials that adapt to the environment, medical devices that sense and respond to subtle biological rhythms, engineered cells that use nature’s building blocks to manufacture fuel or attack a disease. But beyond pursuing research in these areas, the institute focuses on transforming its discoveries into devices—transferring ideas from academia into the hands of private industry. The two-year-old institute has a growing project portfolio and institutional and corporate partnerships that have the potential to expand Harvard’s research in new ways. Its applications range from vibrating insoles that could help prevent falls in the elderly to a device that rapidly diagnoses sepsis, a potentially fatal condition.

The institute grew out of a larger initiative at Harvard to develop a vision for bioengineering. One faculty proposal was an institute for biologically inspired engineering; that received seed funding from the University in 2008. The following January, the program received an enormous boost when Swiss entrepreneur Hansjörg Wyss donated $125 million to launch the institute, the largest gift in Harvard history (see “Life Sciences, Applied,” January-February 2009, page 34).

“My goal has always been to improve patient care,” Wyss says. An engineer by training and chairman of the medical-device manufacturer Synthes, he became interested in the effort while meeting with several leaders in biology and medicine at Harvard; he saw an opportunity to create an institution that would help engineers and biologists work together and connect multiple disciplines to solve practical problems.

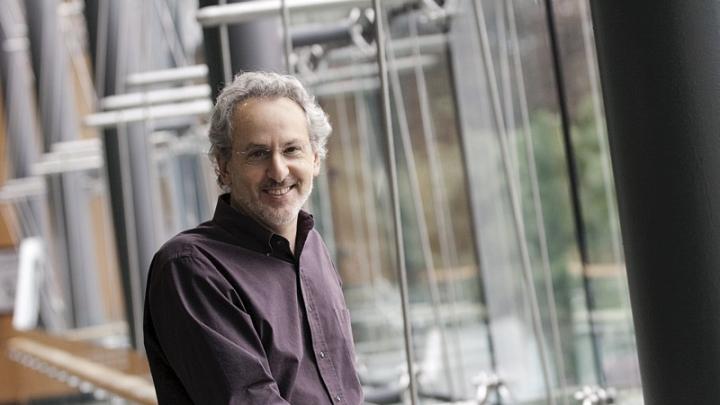

The intention was to build an entirely new organization at the University: not a traditional research center producing discoveries and scientific papers alone, but a place focused on creating new technologies and applications that—thanks to industrial collaborations—can directly benefit both human health and the environment. Don Ingber, Folkman professor of vascular biology at Harvard Medical School (HMS) and professor of bioengineering at the School of Engineering and Applied Sciences (SEAS), was named founding director. (He and David Mooney, Pinkas family professor of bioengineering, were instrumental in developing the original vision for the institute.)

The resulting Wyss Institute is, Ingber says, like “a start-up in the midst of the world’s greatest academic environment.” Wyss himself says Ingber “has done a fantastic job” in moving the institute’s work forward. The institute is not housed within any Harvard school; its research staff includes 16 core and several associate faculty members representing the Faculty of Arts and Sciences, HMS, and SEAS, as well as Boston University, the University of Massachusetts Medical School, Beth Israel Deaconess Medical Center, Brigham and Women’s Hospital, Dana-Farber Cancer Institute, and Children’s Hospital Boston. The institute also has its own technical and administrative staff, and office and lab space in both the Longwood Medical Area and Cambridge.

The institute’s work aims to use lessons learned from biology to develop engineering innovations, Ingber says, because science has recently generated a great deal of fundamental knowledge about how living systems work. “We’re really beginning to understand how nature builds,” he explains. Those insights can be brought to bear on a wide array of disciplines, including materials science, architecture, medicine, computer science, and engineering. New engineering tools, meanwhile, make it possible to interface with biological systems in novel ways.

Perhaps most important, by bringing together scholars whose work already bridges traditional departmental divides—through fields such as genomics, tissue engineering, synthetic biology, and robotics—the institute offers opportunities for unexpected collaborations that can advance research even more. And rather than housing investigators’ individual work in separate labs, Wyss projects are organized into six Enabling Technology Platforms, each focused on developing new technology capabilities that could have numerous applications.

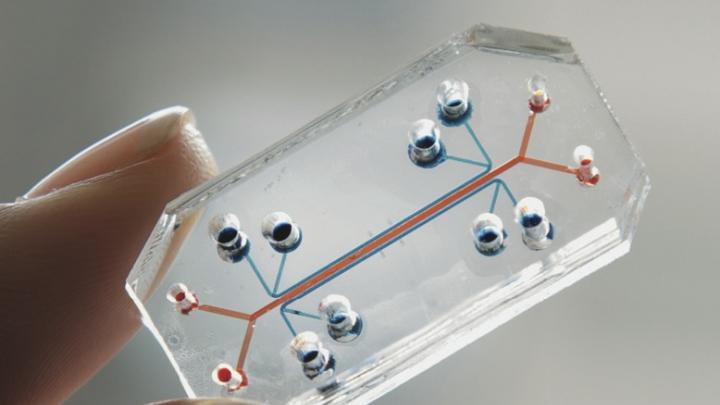

Ingber is leading a project in the Biomimetic Microsystems platform that creates microchip-like devices containing living cells that can mimic the functions of real organs. Last June, the team announced that they had made a flexible, coin-sized chip containing chambers of human cells that reproduce the workings of a lung, even “breathing” by stretching and relaxing in response to changing air flow. Pharmaceutical companies are beginning to partner with institute researchers to explore whether these devices can be used to develop drugs and perform toxicology screenings without relying on laboratory animals. Meanwhile, the team’s system for rapidly diagnosing sepsis is a significant advance beyond current practice, where identifying this dangerous condition definitively can take days.

Not all applications have a medical focus—others will affect the environment or improve industrial design and manufacturing. The Bioinspired Robotics platform, for instance—building on work by assistant professor of electrical engineering Robert Wood, its co-leader—is designing small, delicate robots that look like houseflies; such devices could help pollinate crops in places where bees are threatened (see “Tinker, Tailor, Robot, Fly,” January-February 2008, page 8). Berylson professor of materials science Joanna Aizenberg is leading efforts in the Adaptive Architecture platform to develop materials with special properties inspired by objects in nature; lotus leaves, for instance, are extremely efficient at repelling water, and the Wyss team seeks to capitalize on this property to develop a material that could prevent ice formation on airplane wings.

Ingber explains that the platforms—the others are Anticipatory Medical Devices (developing electronic devices to detect and prevent medical problems before they happen), Programmable Nanomaterials, and Biomaterials Evolution—create a structure in which projects can build on one another; one platform may enable many different types of applications or fields of research. In choosing projects, the institute’s leaders emphasize high-risk ideas that might not obtain support from conservative funding agencies that typically emphasize incremental advances.

The Wyss is meant in particular to help speed to market new products that might otherwise languish in research laboratories. An early example is a project initiated by James Collins, a professor of biomedical engineering at Boston University: vibrating insoles that can help prevent falls in the elderly. Collins had developed the technology in his lab, based on 15 years of work demonstrating that a small amount of noise introduced into certain systems can enhance the detection of a signal; in this case, providing faint random vibrations to the feet—so faint they are undetectable—actually boosts the sensory system’s ability to detect balance cues. He has found that elderly people exposed to these vibrations can maintain their balance as well as much younger adults.

Wyss points to Collins’s project as an example of how the institute can be transformative; a project like this, he says, “needs more than just a professor.” Collins explains that the technology, though promising, had fallen into a gap where many academic projects stall: funding agencies support basic scientific work, he says, whereas “companies and investors generally want to invest in products, not projects.” Moving beyond proof of principle requires a complete prototype that can be demonstrated to companies.

“The Wyss is incredibly well positioned to fill this gap,” Collins says. He and a team there are working to transform the technology into a product, create a commercialization plan, and reach out to shoe and insole companies. Meanwhile, David Paydarfar, a Wyss associate faculty member based at the University of Massachusetts Medical School, is using related scientific techniques to develop a vibrating mat for newborns that could prevent sleep apnea, a potentially fatal problem in which breathing stops.

To turn ideas into commercial applications, the institute draws on professionals from various sources. Its administrative leadership has experience working in industry, and its staff includes an “advanced technology team” of more than two dozen technical experts drawn from both academia and industry who can guide the transformation of technologies into materials and devices. Although faculty members at the Wyss will continue to solicit grants and write scholarly papers, the goal will be to generate intellectual property, royalties, and investment opportunities.

A key innovation facilitating the Institute’s work was the creation of a universal contract for all collaborations, streamlining the often onerous process of connecting people at multiple institutions, nonprofit and otherwise. To promote collaboration, the contract requires that work take place on site.

To further the applications it develops, the Wyss has actively courted partnerships with industry. In November 2010, for example, it announced a multiyear partnership with Agilent Technologies; the company will support the development of tools and technologies in three platform areas: Biomaterials Evolution, Programmable Nanomaterials, and Biomimetic Microsystems.

“I think this is a terrific opportunity for Harvard,” Wyss says. He believes that other universities are already seeking to replicate the institute’s approach, both in bringing disciplines together and in emphasizing commercial applications of its work. For Ingber, the excitement clearly lies in having such resources and expertise in one place, in order to move projects forward quickly. He says that faculty members have been drawn to the Wyss because of the promise of accelerating their work, taking on riskier projects, and seeing them move more quickly beyond the laboratory into the real world.